Big Data in Logistics: How Data Analytics Changes the Industry

Digital technologies enable organisations to compile unimaginable amounts of data, including logistics companies. Therefore, these businesses should leverage the data they collect because this often contains the key to better products and services.

When applied correctly, big data in logistics can have a profound impact on company performance as well as the industry-wide outlook.

Online retailers record and analyse terabytes of information about their customers to create personalised recommendations. Similarly, logistics companies need to collect information from all relevant points, store it, and analyse it in order to make business decisions.

Big data in logistics helps business owners transform huge amounts of information and use it to their advantage. But how exactly can you transform such substantial data sets into actionable insights?

This article will explain how big data analytics in logistics works and what benefits companies can gain from this practice. We’ll also share some of the ways that big data analysis can improve transparency and overall productivity in your logistics business.

What is data analytics?

Data analytics is the process of extracting critical information from unprocessed data. If done correctly, this practice allows companies to identify hidden patterns and tendencies. These, in turn, can be used to create strategies that lead to business improvement and faster growth.

The analysis of information is vital for logistics and transportation companies because each data set represents an opportunity to improve.

As a matter of fact, many logistics companies already use big data analytics to modify their products, improve customer services, and identify organisational areas of improvement.

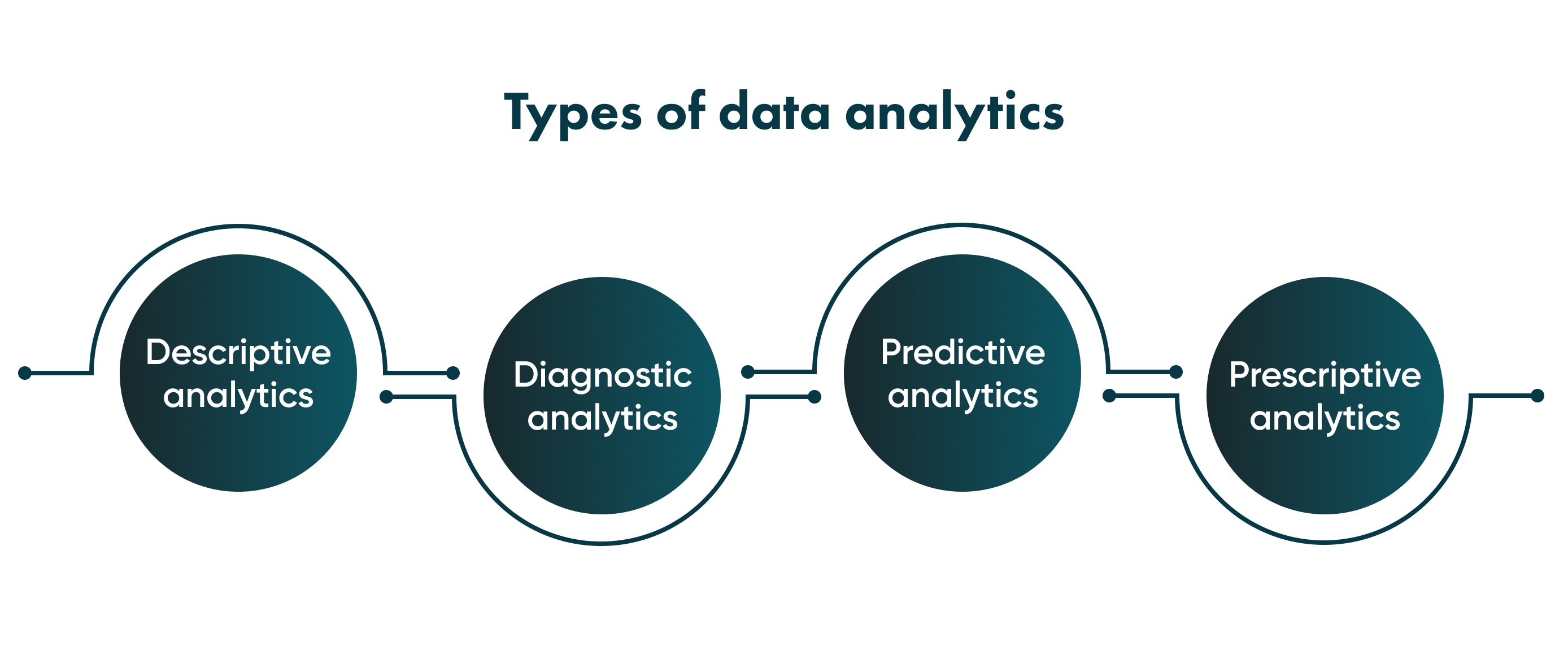

There are four types of data analytics in this business context:

- Descriptive analytics: Information that describes what happened over a period of time. For data analysis in logistics, this can be something like car mileage.

- Diagnostic analytics: Details that are used to identify the causes of an event. For example, determining the cause of a failure using an audit log.

- Predictive analytics: This type of analytics is used to predict future occurrences. Big data in logistics can help companies avoid future issues and predict better conditions.

- Prescriptive analytics: Prescriptive analytics are used to identify the best actions based on predicted scenarios. Here, specialists create a plan to deal with potential setbacks.

The importance of big data for the logistics industry

Big data processing is valuable for many industries, and the logistics sector is not an exception.

In transportation and logistics, big data consists of huge volumes of heterogeneous information collected from a constantly growing set of sources.

Said in simpler terms, logistics companies collect information of various types and from countless sources.

The problem is that it’s not possible to process all this information using conventional manual methods.

Fortunately, big data processing technologies make it possible to accumulate, store, and analyse information and then get valuable insights for business.

By using big data processing technologies, logistics companies can use input from various sources and turn them into productive information to make the right decisions.

For example, transportation and logistics service providers collect data like the size and weight of packages, shipment location, and destination. Then, they can transform this data into actionable information.

For example, determining the best way to send a specific number of packages from one destination to the next using the fewest possible resources.

As a result, companies can become more efficient, get acquainted with the latest market trends, analyse customers' purchasing patterns, and so on. This, in turn, means that big data can lead to cost reduction.

How big data works in logistics

There are different ways to work with big data.

Companies with enough resources can hire a team of engineers to develop their own infrastructure for processing and analysis.

However, more often than not, companies use ready-made tools that provide services like report generation and accounting and help analyse big data.

Some tools make it possible to search for an optimal rate for a specific destination to deliver goods. This search is available based on an analysis of rates extracted from open sources, but is not personalised to the company’s specific metrics.

Plus, out-of-the-box solutions often leave a lot to be desired in terms of security and overall performance.

Your best bet is always to opt for a custom big data analysis platform. This may represent a bigger investment, but it can exponentially boost the performance of your logistics business.

How do you plan to work with big data in your business? Contact Go Wombat - we will help you apply big data solutions that improve your business.

The benefits of big data in logistics

In this section, we’ve listed the advantages of using big data tools in logistics.

1. Plan freight and trips more accurately

When organising transportation, estimating how quickly vehicles will get from point A to point B is challenging since there are many factors to consider. This includes operational working processes of warehouse workers, traffic jams, road conditions, gas station locations, among others.

If you analyse the combination of factors by gathering data from open sources, you can effectively plan routes and manage the work of warehouses.

Also, there are often challenges during last-mile delivery, which is the last stage of shipment to the customer.

Drivers must find an optimal route to reach their destination quickly whenever there’s a last-mile delivery issue.

Usually, it takes a lot of time for drivers to figure this out. However, if the freight company analyses maps and considers all road characteristics, it can create optimal routes in the last-mile delivery stage so that cargo will be delivered faster.

This is just one of the ways that big data analytics in transportation can come to the rescue.

2. Create better equipment maintenance regimes

If companies don’t use big data-based solutions, they may have to conduct maintenance and repairs more frequently, which represents a loss of profits.

In addition, companies that don't employ big data aren’t usually aware of the precise condition of the equipment they use. When this occurs, malfunctions occur without warning, so the affected company needs to spend money to fix the equipment or even buy a new one.

The solution is installing sensors on trucks and other equipment to gather information about their condition and the degree of their deterioration. It will help perform technical maintenance timely.

3. Reduce risks

When companies consider the equipment condition and monitor weather and road conditions, they can contribute to freight safety and help reduce risks from all angles.

For example, companies can gather information from installed thermometers and acoustic and visual sensors on equipment.

As a result, logistics companies won’t use trucks that may malfunction due to wear and tear — which reduces the likelihood of an accident as well as cargo damage.

4. Track and monitor cargo location in a warehouse

Data analytics in logistics make it possible for companies to install sensors on all items and use video surveillance systems to find the required object and monitor it at each processing stage.

Big data can also optimise warehouse workflow.

Also, the information about the flows of goods helps determine the fluctuation in demand and seasonality.

For example, if there is an influx of orders that need to be delivered to a specific destination in July, you would know in advance and therefore could prepare for them in advance.

5. Optimisation of the packaging process

In some instances, warehouse employees are responsible for packaging as well as shipping line items.

Here, it’s common for companies to experience a loss in resources due to poorly selected packaging. Poor packaging can actually prevent parcels from being loaded into trucks, thus causing delays.

With big data, companies can pre-pick the best-fitting package. Then employees can simply get instructions by scanning each piece of cargo before packaging.

6. Carrier ratings

You need to evaluate performance in order to increase the safety and efficiency of transportation and big data analysis will help you.

When you make decisions based on big data, you reduce the loss due to theft. Not only this, but there’s enough data to change carriers as soon as it becomes a problem.

When you analyse carrier ratings from different companies for an extended period among other data, you can decide who you can work with.

7. Information about drivers

Many companies create databases of drivers and choose who to work with in order to avoid transportation problems as well as disputes with customers.

Big data analysis makes it possible to verify drivers based on their history and performance before deciding whether or not to work with them.

8. Solvency and financial growth

It’s essential for businesses to be solvent and take steps to experience financial growth. Big data analytics can help transportation companies retain contract signing with clients who have unfulfilled obligations to other carriers.

Create a big data solution for logistics purposes — Go Wombat will be your software development partner. Contact us!

Real use cases of big data analytics in logistics and supply chain management

It is always a good idea to analyse how other companies use big data in supply chain management and logistics. So we created a list of real-life use cases for you to understand what you can achieve with big data so far.

Transportation of goods with special conditions

The delivery of perishable goods, hazardous materials, and frozen food is more challenging than conventional transportation.

As a carrier, you must ensure the best storage conditions to deliver the cargo safely to the destination.

For example, take Swiss start-up SkyCell, which has created containers for medical transportation. These containers contain sensors to measure temperature and collect data about vibration levels.

Additionally, the sensors send information to the developed software where all reports are generated. As a result, such containers are used today by many companies to organise medical delivery properly.

Routes optimisation

As we mentioned before, big data in transportation is critical to optimise routes and ensure timely delivery. If you don’t deliver cargo on time, it will be a blow to your reputation as a logistics company.

However, you need to consider so many conditions for route optimisation, from traffic jams to weather conditions.

To address this, the shipping company UPS integrated the ORION (On-Road Integrated Optimization and Navigation) algorithm into their software.

Once the driver starts his or her work, the system builds an optimal route for them. The ORION algorithm uses descriptive and predictive analytics to forecast potential problems. ORION has information about more than 60,000 routes around the US, Canada, and Europe.

Demand forecasting

Leading companies constantly strive to be proactive, so they want to sell goods people need right now. These organisations often use big data algorithms to forecast demand.

Domino’s Pizza, for instance, uses data that has been collected for years. This company employs big data to know what pizza will be ordered on specific days at distinct times, so they prepare everything in advance to deliver their products quickly.

Simply put, when someone orders a pizza, it is almost already baked. Thus, demand forecasting allows Domino’s Pizza to deliver great service to its loyal customers and attract new ones.

Warehouse management

Large warehouses can be a nightmare if workers don’t use modern technologies to monitor the supply and delivery.

Amazon Robotics is a great example of how big data, internet of things (IoT) technology, and robotics create an intelligent warehouse and automate logistics processes.

The company uses mobile drive unit robots in its warehouses as well as in the order fulfilment process. Big data is the main driving force behind the robots.

Big data algorithms process vast amounts of data to control and manage robots. For example, algorithms may determine how many bots should be deployed, their routes, their optimal speed, and so on.

Logistics cost reduction

Logistics companies certainly want to reduce fuel and repair costs, so big data analytics is the right approach to it.

Moreover, decreasing logistics expenses may enable you to make business development and growth investments.

DHL has created a Smart Truck solution to reduce logistics expenses. Now, some DHL trucks are equipped with IoT-enabled sensors which collect data about road and weather conditions and routes, among other variables.

This system, which relies on big data to collect and parse the information, then provides route optimisation. Not to mention, it also helps reduce fuel consumption, which means reduced fuel expenses.

Safety of drivers

The safety of drivers implies the safety of cargo, timely delivery of freight, and reduced problems. Logistics companies must take care of their drivers to ensure they won’t get in a road accident.

Fleet Risk Advisors has created big data-based software to collect information about drivers, their working hours, truck speed, route, and other variables. As a result, the company knows when drivers need to rest, reducing road accident risks and optimising expenses.

Leveraging big data in your transport and logistics company

Your next move is to decide what software your company needs to create for your logistics niche.

Big data can be used for a huge range of applications, so it’s important to identify all applicable areas before implementing this approach into your business.

At Go Wombat, we work with technology like IoT, AI, machine learning, computer vision, and, of course, big data. But the list doesn’t stop there. Our team has extensive experience in software development with complex algorithms.

Remember that big data technology can be made to suit your logistics needs. If you want to know more about optimising your logistics business with big data, contact our team and we’ll be glad to help.

Unlock Success with Premium Software Development

Contact us

FAQ

What is data analytics in logistics?

Data analytics in logistics is the process of analysing and transforming large data sets into actionable information in order to be used in a logistics business.

Simply put, data analytics helps companies store, process, and analyse huge amounts of information to use for business advantage and growth.

How is big data used in logistics?

Big data in logistics has dozens of different uses. The most widespread ones are route optimisation, freight planning, equipment monitoring, warehouse management, and predictive analytics, but these are not the only options.

Why is big data important in logistics?

Big data algorithms make it possible to improve logistics operations and provide better customer service. In addition, they help managers predict the future situation in the market and build competitive strategies, resulting in better business performance.

How can we help you ?