The Essentials of Custom ERP for the Oil and Gas Industry

The oil and gas industry is one of the world's most complex and dynamic sectors. It involves the exploration for, extraction, production, and transportation of oil and gas, as well as the processing and refining of these resources into a range of consumer goods.

As a result, the industry faces many challenges, including volatile markets, changing regulations, and the need for efficient and cost-effective operations.

To tackle these challenges, many companies in the oil and gas industry are turning to enterprise resource planning (ERP) software solutions to improve their operations and increase their bottom line.

This article will highlight the key features of custom ERP software for the oil and gas industry and the benefits that this software can bring to companies operating in this complex field.

Why is an ERP system necessary for the oil and gas industry?

We mentioned above that the oil and gas industry is very complex because it involves the completion of many work processes that have to be optimised.

Let’s take a look at the role that ERP can play in these areas.

How ERP can help

An enterprise resource planning system can help oil and gas companies by providing a comprehensive, integrated solution for managing their business operations. An ERP system can:

- Improve supply chain management

- Automate key business processes

- Gain better visibility into the company’s operations.

In addition, ERP systems are perfect tools for managing finances, human resources, and customer relationships, providing a single platform for all business needs of the oil and gas company.

Not to mention, an ERP system can help companies in the oil and gas industry comply with industry-specific regulations and standards, such as those set by the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA).

By automating compliance processes, an ERP for the oil and gas company can reduce the risk of non-compliance and associated penalties, improving overall safety and sustainability practices.

Overall, an ERP system is an essential tool for companies operating in the oil and gas industry, helping them streamline their operations, improve compliance, and increase profitability.

Now, is it necessary to create an ERP system from scratch?

Considering a customised solution

There are many existing ERP solutions that you can use for your oil and gas business. But, while more affordable, an off-the-shelf solution won’t meet all your needs since existing ERP systems contain general features and cannot cater to all possible user requirements.

Therefore, it’s always best to opt for a custom solution built from scratch to get the best out of an ERP system and achieve your goals faster.

Custom ERP solutions for the oil and gas industry can become resource-intensive and time-consuming, but you can build an enterprise resource planning system tailored to your oil and gas company's requirements.

For more, read our detailed article about ERP system development and the benefits of a custom solution.

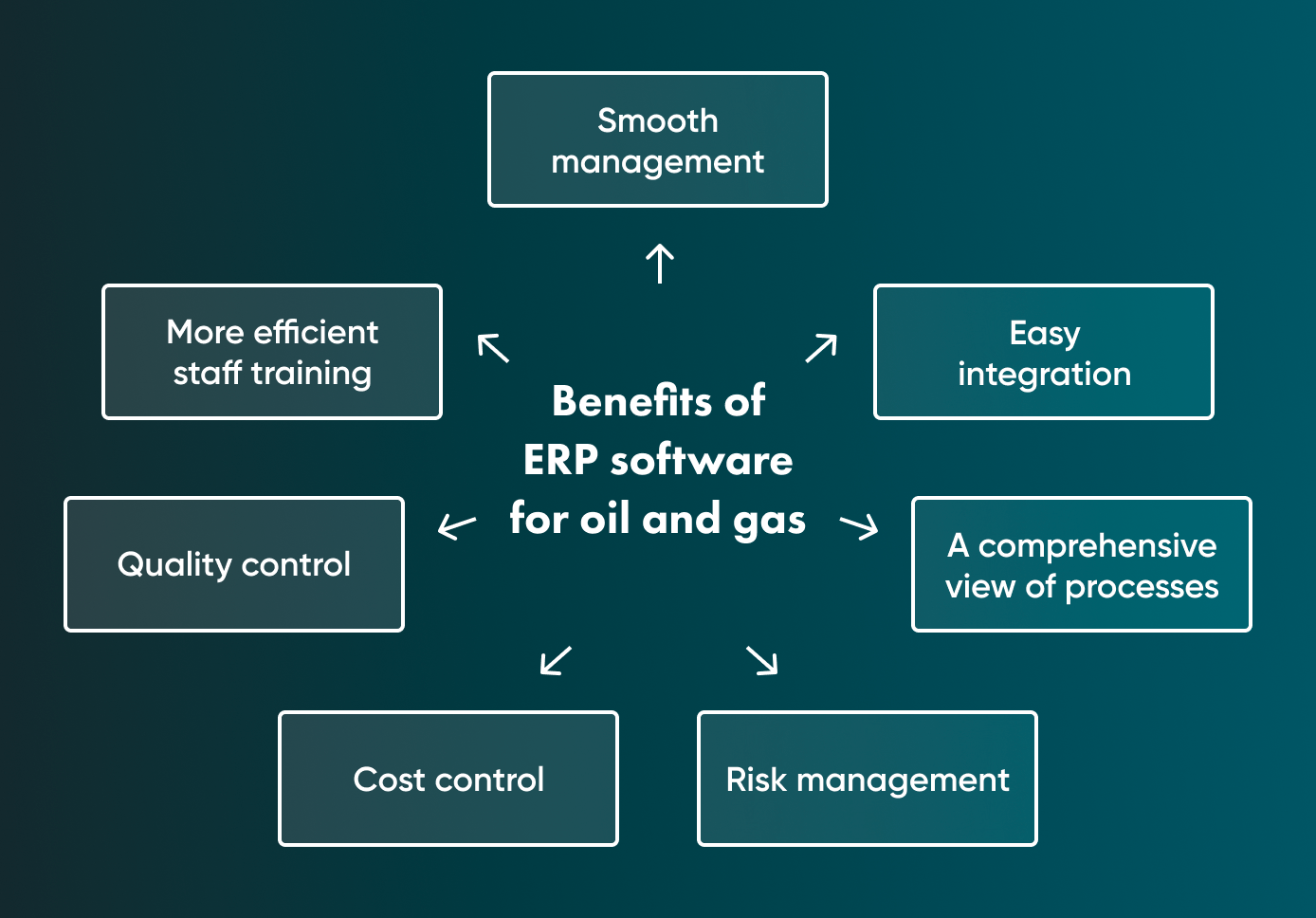

Benefits of ERP system for the oil and gas sector

Besides the reasons for developing a custom ERP system, we can also single out why it is a must-have software for your business.

Smooth management

The various oil and gas exploration and production processes are critical and risky, so they must be effectively monitored and managed. These processes include rig management, land and water management, site engineering, and compliance adherence.

ERP systems provide real-time access to information, empowering users with critical business data and helping them make crucial decisions. They also ensure interdepartmental communication, boosting productivity and efficiency.

Easy integration

A powerful ERP for the oil and gas industry can be easily integrated with other business applications, enabling you to monitor resources and expenses across your organisation. In addition, it can help in meeting production deadlines and deliveries.

A comprehensive view of processes

Enterprise resource planning software has client and server-side capabilities that can be customised to meet your needs. It provides overall visibility into your company's processes, helping you meet compliance and adhere to regulations. It also allows supervisors and managers to check employee progress in real-time, boosting employee morale and productivity.

Risk management

ERP software can help oil and gas businesses to recognise the risks in a project early on, so that engineers and managers can have a clear picture regarding what to expect and the project's potential success.

Cost control

An ERP system in the oil and gas industry can help you manage your supply and demand chain more effectively. It also allows you to maintain compliance with legal requirements and industry regulations, especially for international transactions.

Quality control

In the oil and gas industry, quality control is a crucial aspect. ERP software is useful here because it can help track loss in distribution to minimise incidences and help with compliance reports in purification and refining. The losses may be solid, liquid, or gaseous — ERP software can help record and understand these transformations.

More efficient staff training

Implementing an enterprise resource planning system can help an organisation transfer vital technical information to new engineers and technicians. In addition, the ERP system can easily integrate recruits into various processes like energy exploration, monitoring, production, and refining.

Already have an idea about what you need? Then contact Go Wombat and share the info about your upcoming project.

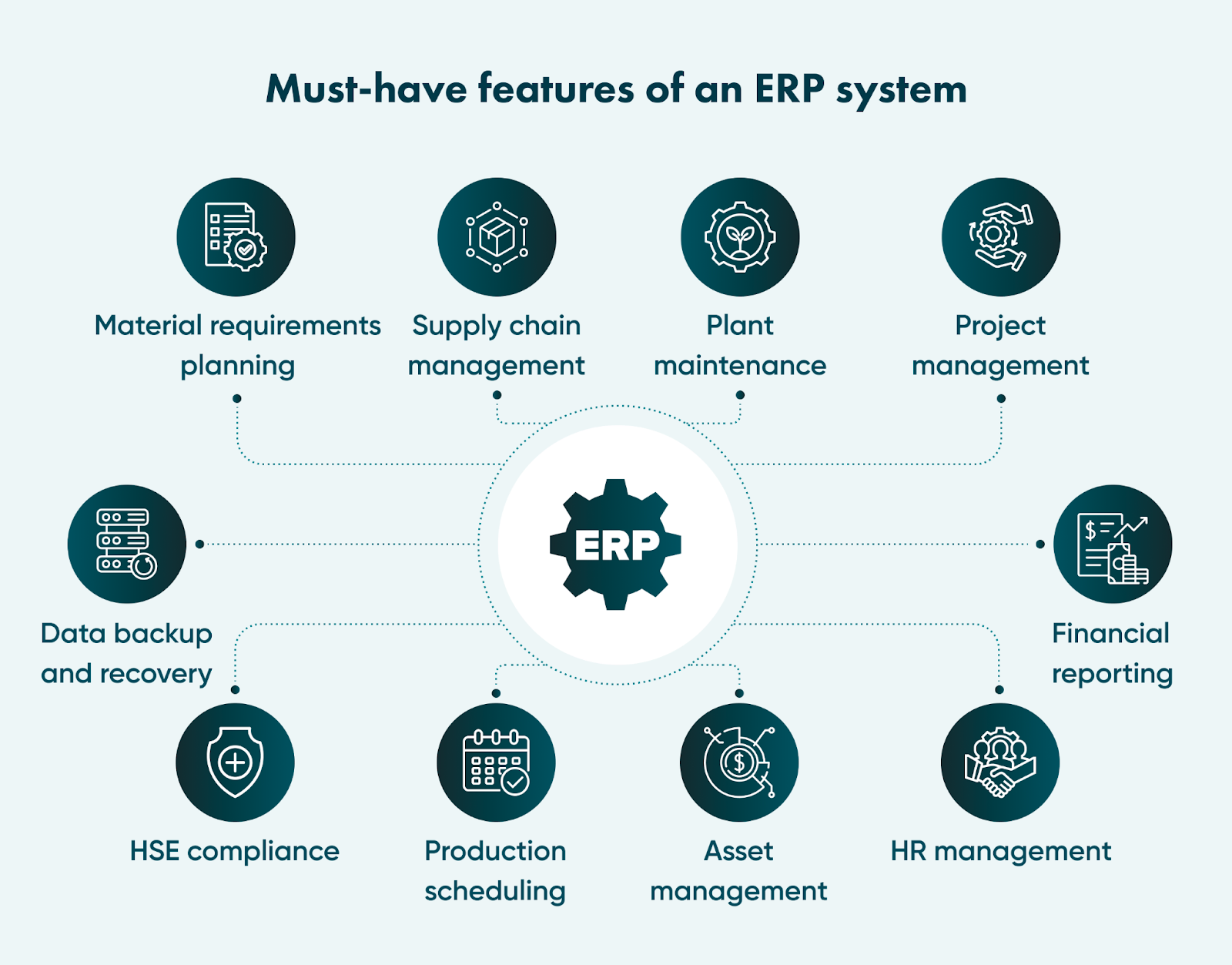

Features an oil and gas ERP system must include

Your future ERP for the oil and gas industry may have various features depending on your business’s requirements. However, there are some primary features every ERP solution should contain, so let’s review them below.

Material requirements planning

This module helps in planning and scheduling the production and procurement of raw materials and components needed for the manufacturing process in the oil and gas industry.

Supply chain management

This feature is required to manage the procurement, storage, and distribution of materials, equipment, and products across the supply chain network.

Plant maintenance

Using this feature, you will be able to maintain the equipment and assets in the oil and gas industry by scheduling and tracking preventive and corrective maintenance activities.

Project management

It is vital to manage all the projects efficiently so that you can plan, schedule, and execute projects, including exploration, drilling, production, and transportation.

Financial reporting

An ERP system must help you with financial issues. This feature should allow you to manage typical financial operations of the oil and gas industry, including accounting, budgeting, and reporting.

HR management

HR management is an essential feature of ERP systems that helps companies manage their human resources. This module helps manage the workforce and handle all related HR tasks like recruitment, training, performance management, and compensation.

Asset management

The ERP system provides a centralised database of equipment and assets, including their location, condition, maintenance history, and depreciation value. Also, the system generates reports and analytics on asset performance, such as availability, reliability, utilisation, and efficiency. This helps identify areas for improvement and optimise asset performance.

Production scheduling

An oil and gas ERP software should include scheduling capabilities for production and refinement. In addition, the system should easily handle the schedule management of all departments, whether for a single unit or high-volume segments. This way companies can finish projects on time without manual labour and calendar checks.

HSE compliance

HSE stands for health, safety, and environment. With this feature, safety managers will be able to ensure the safety of workers, compliance with environmental regulations, and the protection of natural resources in the oil and gas industry.

Data backup and recovery

An oil and gas ERP system includes sensitive data and international schedules, which must be adequately protected. Data backup and recovery features allow admins to back up data in a secure cloud-based system with security measures to prevent theft or data leakage.

How much will you need to pay for oil and gas ERP system development? Let Go Wombat make a detailed estimate for you — contact us!

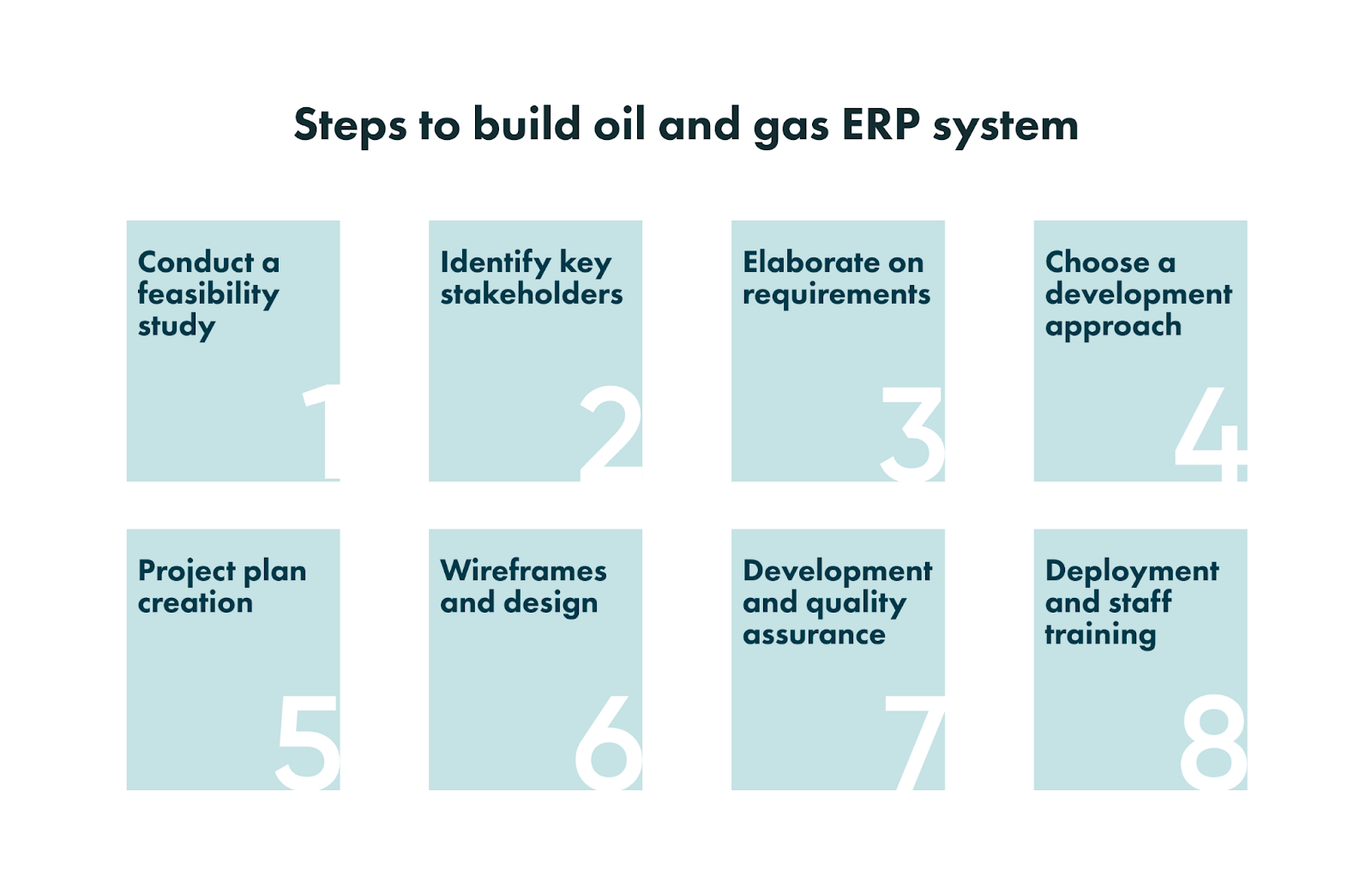

8 Steps to develop an ERP system

What key steps should you take to create ERP solutions for the oil and gas industry? Of course, you can’t go straight into software development – you must take into account other crucial stages.

Let’s break those down here.

1. Conduct a feasibility study

You must evaluate the business processes and requirements of the organisation to determine if an ERP system is necessary and exactly what type of tool is feasible.

The feasibility study includes assessing the benefits, risks, and costs associated with implementing an ERP system.

This can help stakeholders make informed decisions about whether or not to develop such a system and, if so, how best to approach its development and implementation.

2. Identify key stakeholders

The next step is identifying the key stakeholders involved in the ERP implementation project, including executives, functional and technical teams, and end users. You must ensure that all parties are aligned and engaged throughout the project.

Identifying key stakeholders is essential in developing an oil and gas ERP system, as these stakeholders play a critical role in the project's success.

3. Elaborate on requirements

Requirements identification is essential when creating an oil and gas ERP system. This process involves gathering and analysing data to determine the needs of the organisation and the features that must be included in the system.

It is necessary to draw up a detailed description of the processes and functions that must be supported by the system and the data that must be collected and stored. It should also include any specific security, scalability, and performance requirements. Once the requirements are defined, the development team can use them to create a system that meets the needs of your oil and gas business.

4. Choose a development approach

Once the requirements are defined, the next step is to choose a development approach.

This may involve developing the system in-house, outsourcing development to a third-party provider, or combining both.

However, software development outsourcing remains one of the most attractive and profitable ways to build your software.

Even though a development company might be located in offshore regions, it will charge lower hourly rates than the companies in your area. And, while in-house software development lets you control the programming team entirely, you will face additional expenses like hardware and software purchases and additional office rent.

If you want to dig deeper into how to outsource software development efficiently, we have a detailed article on the subject.

5. Project plan creation

Your project plan should outline the timelines, milestones, and deliverables for the ERP implementation project. You can do it independently, but it will take much more time, especially if you don’t have expertise.

That’s why we recommend that you with professional developers instead. At Go Wombat, our business analysts can create a detailed plan for your project, including risk assessment, requirements identification, and other crucial points.

6. Wireframes and design

The next step is determining what designs, roles, and rough drafts of features you want to include. Then, UI/UX designers should then create wireframes aligned with your expectations.

Each section should have different ideas based on functionalities, finance management, CRM (customer relationship management), and other relevant departments.

7. Development and quality assurance

In this step, your developers build the oil and gas ERP system, and then QA engineers test it to ensure it meets the functional and technical requirements. This may involve iterative development cycles to refine the system over time.

8. Deployment and training

Now, you must consider the next step — ERP system deployment in the production environment. The deployment will include migrating data from existing systems, configuring the system for specific business needs, and training users on how to use the system.

Finally, don’t forget about system maintenance. Our development team have the ability to keep working on this project to maintain and support it after its release.

Summing up

Overall, oil and gas ERP software development is a complex process that requires a deep understanding of the industry, its operations, and the customer's needs.

Therefore, choosing the right ERP software development partner is critical to ensure the project succeeds and meets the customer's needs.

With the right combination of knowledge, expertise, and experience, oil and gas ERP software development can be a powerful tool for streamlining operations and increasing efficiency.

And that’s the kind of right combination you’ll find at Go Wombat. We have the know-how to build an ERP system suited for your oil and gas organisation.

Contact Go Wombat — let’s start developing an ERP made with your business in mind.

Unlock Success with Premium Software Development

Contact us

FAQ

Does the oil and gas industry use ERP?

Yes, companies in the oil and gas industry commonly use enterprise resource planning (ERP) software to manage their operations. ERP software helps organisations integrate and manage business processes such as finance, procurement, production, supply chain, and human resources.

In addition, ERP software allows for managing exploration, production, refining, transportation, and distribution operations in the oil and gas industry.

What can an ERP Solution do for oil and gas companies?

An ERP solution can be an excellent asset for oil and gas companies. It can provide many benefits, such as smooth management, a comprehensive view of processes, cost control, risk management, and so on.

ERP solutions help streamline business processes, automate data entry, and provide real-time visibility into operations. This is why ERP software can give oil and gas businesses the tools they need to succeed in today's competitive market.

What is an ERP solution for oil and gas?

An ERP solution for the oil and gas industry is a comprehensive software system that helps companies manage their operations more efficiently.

An ERP solution can provide a unified platform to manage all aspects of their business, from accounting and finance to inventory, supply chain management, and customer relationship management. Furthermore, an ERP solution can offer advanced analytics and reporting capabilities to help companies make better decisions and optimise their operations.

How can we help you ?