How Artificial Intelligence in Supply Chain and Logistics Transforms the Industry

Information technologies have integrated themselves into our lives. So the concept of artificial intelligence (AI) probably isn’t too foreign to anyone these days. Many of us already use AI-based mobile voice assistants like Siri, Cortana, and Google Assistant in our day-to-day lives. Yet, we don’t automatically think about AI in supply chain scenarios.

AI is also actively integrated into multiple industries — hospitality, healthcare, and logistics – just to name a few. But, the logistics industry is one where AI proves its efficiency, and we can see that this sector benefits from various digital technologies. This can improve supply chain solutions and logistics as a whole.

AI in supply chain and logistics will be the main topic of this article. We will cover the advantages, use cases, and possible challenges of AI in logistics. So, if your business requires AI-based solutions, our article (and Go Wombat’s specialists) are at your service.

Of note, Go Wombat uses Python as the core language for AI-based software development (see our article about Python for more).

But, first things first.

What AI means for the logistics sector

Digital transformation is a multi-step process that logistics companies must take if they want their business to grow.

Artificial intelligence improves logistics since it takes the digital transformation process to a whole new level. However, it is crucial to consider the following nuances before applying AI to the supply chain.

IT infrastructure

Companies should adjust their IT systems to make them flexible and adaptable to enable the integration of new technologies.

Data management

It is crucial to create a uniform standard for information sources and appropriate pipelines used for real-time data.

Trained staff

Any company planning to integrate AI into business processes should have trained personnel and data scientists skilled enough to work with complex AI algorithms.

So, is AI a good alternative for logistics companies?

As we’ve hinted at before, logistics is one of the most attractive sectors for using machine learning and artificial intelligence. This is because most logistics companies have realised that using AI gives them an advantage and makes them competitive.

Logistics companies started the digital transformation, applying AI as a robust tool to enhance their businesses and take them to a new level. Machine learning in logistics makes it possible to automate multiple processes and save time.

Besides that, machine learning-based processes lead to reduced human errors and make workflow more accurate.

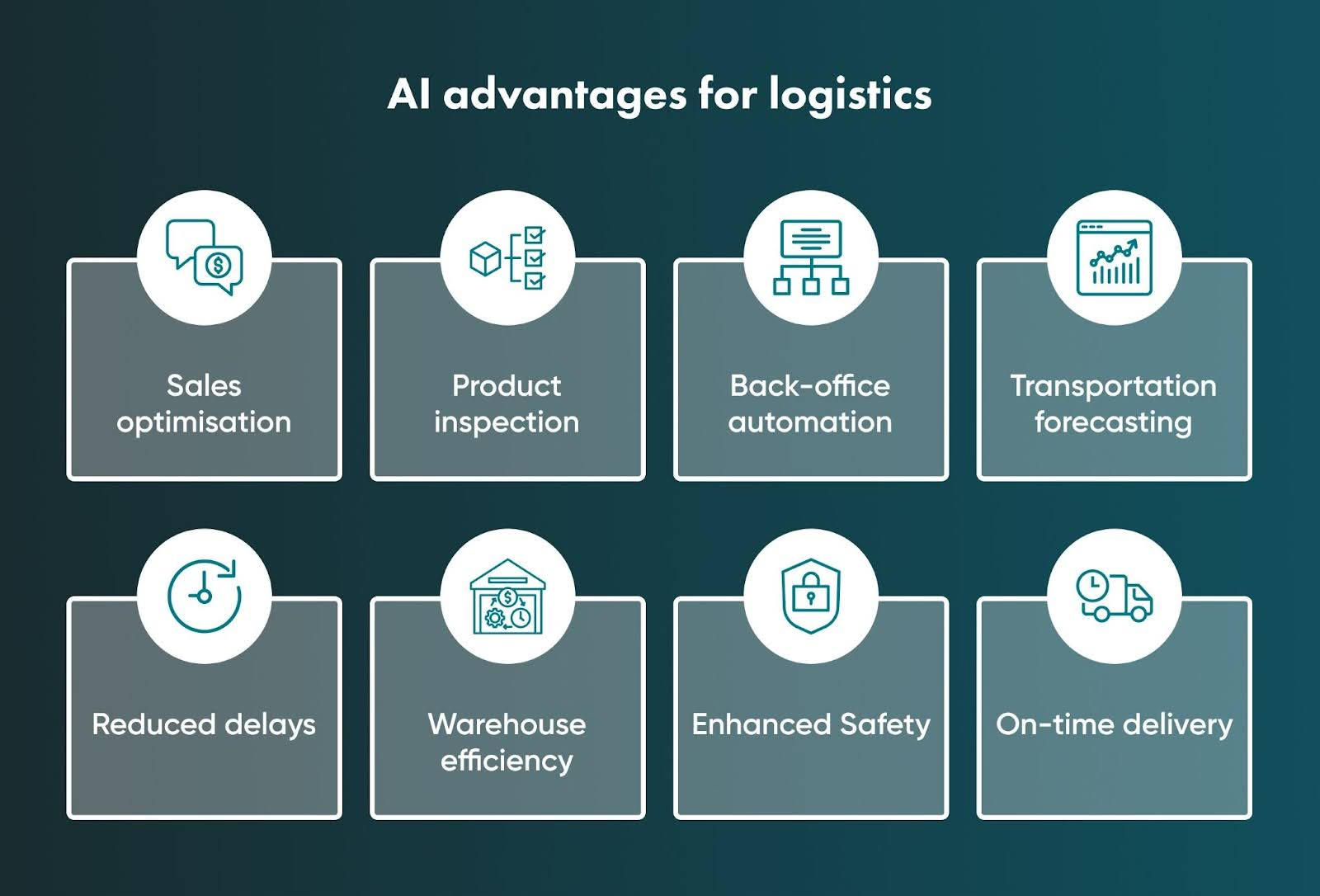

Advantages of AI for the logistics industry

As we started by explaining the importance of AI for logistics, it is important to understand the benefits of artificial intelligence for logistics and supply chains.

Sales optimisation

The AI incorporation simplifies CRM adoption, boosts employee productivity, enables data-driven sales coaching, improves sales forecasting and pipeline analysis, and significantly enhances the sales process, increasing customer loyalty and satisfaction.

Product inspection

Computer vision technology based on AI helps inspect a large number of goods in a warehouse and detect damaged items. Also, AI allows evaluation of the damage type and amount. Installed sensors around the warehouse help enable information collection.

Back-office automation

Back-office refers to the company’s departments that don’t interact with clients (HR, accounting, warehouse). AI applications can become critical for this area of your company. Many routine and repetitive tasks can be automated using AI – supply chain management can be improved, and accuracy will be increased.

Improved transportation forecasting

AI makes it possible to forecast more accurately for transportation, predict shopping capacity needs, evaluate possible price fluctuations in the market, and make better estimations.

Reduced delays

AI-based predictive maintenance helps identify a potential parts shortage in your supply chains so you can take appropriate countermeasures to avoid delivery delays. Moreover, it is possible to predict incoming customer demand and ensure that all clients will have their orders delivered on time.

Warehouse efficiency

With AI algorithms, it is possible to make the workflow of warehouses more efficient and improve the supply chain with automation. AI facilitates speedier warehouse processes, smoother product delivery from the warehouse to the customer, and the resolution of various issues that may arise.

Higher safety

Artificial intelligence can analyse workplace safety data and inform assigned specialists about any potential risks. Furthermore, AI algorithms help manufacturers ensure compliance with all safety standards and avoid accidents.

On-time delivery

The entire delivery process can be more innovative, faster, and safer thanks to artificial intelligence since automated systems speed up conventional procedures, removing operations barriers and reducing bureaucracy.

Planning to integrate AI-based solutions into your business? Contact Go Wombat — we are experts in AI software development.

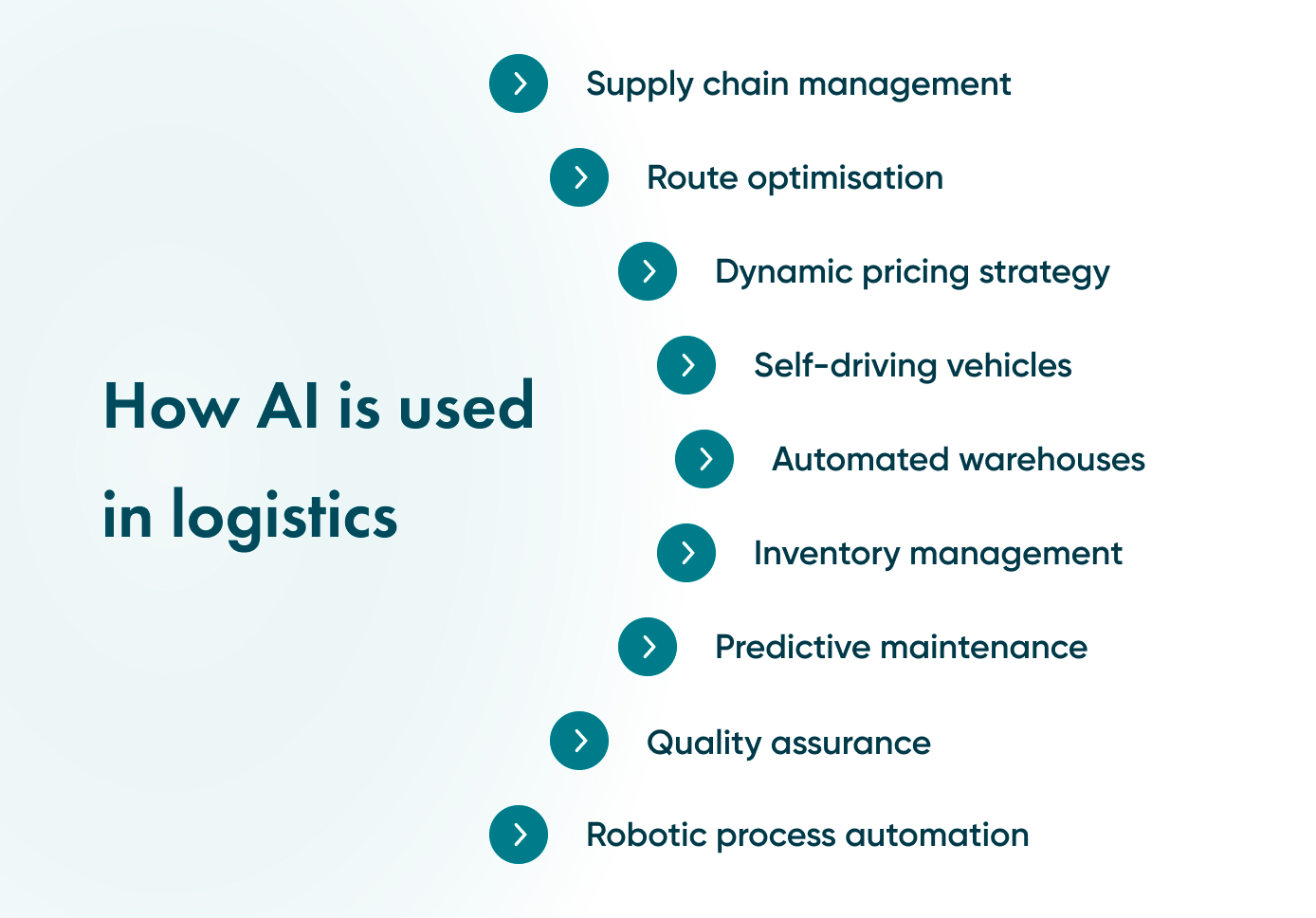

AI use сases in logistics and supply chain

Apart from the benefits of AI, you should understand how you can apply artificial intelligence in your logistics business and how it leverages your business processes.

AI in supply chain management

There are many ways to apply artificial intelligence in supply chain management. AI represents a diverse set of solutions for supply chain issues. For example, it is used to forecast logistics schemes and even customer behaviour, among other trends.

When the COVID-19 pandemic began, many companies had multiple failures in supply chains. It has proved the necessity of AI integration into the supply chain for logistic optimisation. Companies must comprehensively understand the entire ecosystem to avoid critical failures, accurately predict supply and demand, and plan logistics and optimal delivery.

Artificial intelligence and machine learning allow organisations to manage supply chains efficiently, forecast all potential issues, and take appropriate measures to avoid or fix them, creating an automated supply chain.

Route optimisation

With the help of AI, you can optimise delivery routes, saving time and fuel due to shorter distances between destinations.

You can also adjust delivery times precisely depending on demand fluctuations in different regions with AI. In addition, smart logistics systems enable the management and coordination of hundreds of vehicles, leading to lower fuel consumption and better resource allotment.

Besides that, the ability to predict customer demand helps you match that with available transport capacity. As a result, you can plan deliveries more efficiently, considering multiple factors.

Dynamic pricing strategy

One of the ways to optimise logistics operations is to apply AI to dynamic pricing models. You can build proper pricing models considering variables like competitor processes and supply and demand.

AI-based systems help monitor these factors so you can make relevant changes to pricing. Then, you can respond to market changes quickly and multiply revenue. If this system is used adequately, you will be able to increase profits and make your working processes more efficient.

Autonomous vehicles

Self-driving cars use artificial intelligence, and such vehicles are also actively used in logistics. For example, some companies already focus on self-driving trucks that can deliver cargo safely and quickly.

AI technologies allow vehicles to drive from destination A to destination B using sensors and computer vision. Algorithms process incoming data about surroundings, road conditions, weather, and the like to effectively organise delivery.

Yes, autonomous vehicles are expensive, so you need to buy smart cars made by trustworthy manufacturers. Still, this will gradually change the delivery process and help you reduce costs and delays while increasing service quality.

Thus, artificial intelligence in logistics can revolutionise the delivery process.

Automated warehouses

Continuous stable functioning of warehouses is critical.

When it is impossible to expand the space for goods storage, you need to inspect everything in detail and create automated warehouses. Such warehouses are controlled by an AI-based system that manages transportation, retrieval, and goods-placing on shelves.

Sensors are installed on shelves, and high-tech shelves can speed up order acceptance and reception of goods for storage. In addition, automated warehouses allow for reducing manual labour, monitoring stock, and how items are placed on shelves.

Moreover, automated warehouses contribute to increased safety. Robotic equipment will do the hazardous work instead of humans, so your employees won’t be in danger.

Inventory management

If you want to enhance the supply chain, AI-based operations can also enable smart inventory management. It is essential to guarantee that the right amount of items enters and leaves the warehouse. You know how long it takes to process orders, pick and pack them, and monitor everything.

Artificial intelligence-based monitoring systems can scan and report all products that enter the warehouse. As a result, workers don’t need to do it manually, so the process becomes faster as workers can focus on other tasks.

Automated inventory management is critical for the supply chain. AI can make the process smoother and trouble-free so that you can provide a higher level of service. With the advent of artificial intelligence, supply chain management is constantly changing for the better.

Predictive maintenance

Predictive maintenance is the smart maintenance of any equipment used in logistics. Artificial intelligence allows automated monitoring of equipment and helps avoid its failure. Sensors installed inside a device send information to a computer, and specialists can see how it works.

The system uses trained machine learning algorithms and sends an alert if something is wrong before any damage occurs. In this scenario, you’d save a huge amount of resources if instead of repairing broken equipment you knew about all issues in advance.

How can your business benefit from AI? Let Go Wombat be your guide — contact us.

Quality assurance

Artificial intelligence in logistics also changes the game for visual product inspection for defect detection. AI-based computer vision can detect any defects in goods and notify workers about them so that they can replace the item.

As a result, customers won’t get broken products, and their satisfaction will increase, leading to higher loyalty and a better customer experience. Go Wombat has software development expertise that uses AI for quality assurance during manufacturing. We recommend reading our article about it.

Robotic process automation

Robotic process automation (RPA) is intelligent automation intended to automate back-office tasks, as we mentioned earlier, and any other repetitive tasks, with the use of artificial intelligence.

The logistics sector benefits from RPA as companies can enjoy higher accuracy and reduce human errors.

Other solutions like natural language processing (NLP) help automate routine tasks in supply chain management by understanding and processing spoken or written text.

NLP is a subset of AI, and it emulates human interactions with machines using cognitive automation capabilities and advanced data mining.

Challenges that occur with AI in logistics

AI and logistics can work jointly and successfully. However, there are some challenges required for successful AI incorporation in logistics processes.

Let’s take a look at them now.

System complexities

Usually, AI systems are cloud-based and require broad bandwidth to power the system. Also, operators will need specialised hardware to work with AI systems, so you have to keep in mind the investment costs of these necessary tools.

Compatibility

If you use different AI-based solutions, you shouldn’t ignore the fact that some AI systems and hardware may be incompatible, which causes additional difficulties. To avoid this, you can order software development from one company so that all solutions adhere to the uniform standard. Or, you can also work with a firm that prepares detailed documentation about your logistics app.

Training costs

Incorporating AI into your business and the entire digital transformation requires the appropriate skills from personnel. So, you’ll need to undertake some staff training. However, this investment pays off once your employees are appropriately trained and performing.

Final words

Integrating artificial intelligence into your business processes is not something you can do in a day. You need to spend a lot of money and time to ensure it works. However, the result of your effort will prove valuable in the long term as your business becomes competitive and more efficient.

This article explained how you can apply AI in your company, but this list is only partial. We recommend you get in touch with us to discuss your business's nuances so we can build a unique approach to future software development.

So, don’t hesitate to contact us — Go Wombat develops software tailored to your needs to deliver solutions that benefit your business.

Unlock Success with Premium Software Development

Contact us

FAQ

What is AI technology in logistics?

Artificial intelligence technology in logistics can completely change warehouse processes, improve your business, multiply revenue, and make your business competitive.

AI technology in logistics makes it possible to monitor all critical processes and respond to changes quickly.

How is artificial intelligence used in logistics and supply chain management?

Everything depends on your logistics business and individual requirements, but we can list the prominent use cases of AI in logistics and supply chains.

For example, AI can facilitate management all along the supply chain, setting up dynamic pricing strategies, optimising delivery routes, creating self-driving trucks for cargo delivery, managing inventory, performing quality assurance to detect defects, and using predictive maintenance to avoid potential risks.

How does AI work in the supply chain?

AI allows you to analyse data to predict outcomes so that you can optimise your business through AI simulations. Thus, you will be able to identify potential issues.

Also, AI in the supply chain contributes to a better cybersecurity level, so your business will be protected from cyber threats. Besides that, AI helps reduce delays and human errors so operations will be performed more accurately and efficiently.

How can we help you ?