How Predictive Logistics, AI, and IoT Build More Resilient Supply Chains

Supply chain operations get hit with surprises all the time - pandemics, wild weather, you name it.

That’s where predictive AI and IoT step in. With smart forecasting and connected devices, companies can spot risks early and react fast, instead of scrambling after trouble hits.

Here’s why these technologies matter so much now.

Why Predictive AI and IoT Matter in Modern Supply Chains

Predictive analytics digs into all kinds of data - past sales, how suppliers are doing, market shifts - and uses it to figure out what’s coming next. It even pulls in weather and global news to warn you about possible delays before they mess up your plans. Predictive logistics software is all about using real data and smart analysis to make better calls and run things more smoothly.

But none of this works without good data and people who know what they’re doing. Bad data just gives you false alarms. On the other hand, when you’ve got reliable info and a sharp team, you save on operational costs - sometimes up to 15% - and you move faster. The real trick is making sure your predictive AI projects actually line up with what your business needs most.

Predictive AI and IoT also tie together all those scattered systems, turning chaos into something you can actually manage. When you connect IoT sensors to cloud analytics, you get a live, full-picture view of your supply chain. That means quicker decisions and a supply chain design that can handle whatever gets thrown its way.

How Predictive AI Makes Supply Chains Smarter

What’s Predictive AI, Anyway?

Predictive AI takes machine learning and applies it to all the data companies collect - old numbers, live feeds, you name it - to figure out what’s coming next. It’s just one branch of artificial intelligence, but it’s a big deal for supply chains. Think of it as the cousin of generative AI, but instead of creating things, it’s all about forecasting.

Here’s what it looks at:

- Sales and order history, so it can spot seasonal ups and downs.

- Market and pricing data to get ahead of demand swings.

- IoT and GPS signals, to catch transport hiccups or spot gear that’s about to fail.

- Outside stuff like weather or sudden trade issues.

All this helps companies fine-tune their operations and nail their demand planning. The best part? Unlike old-school forecasts that never change, these AI models keep learning. Every new cycle, they get sharper and more accurate.

How Does Predictive AI Handle Demand and Inventory?

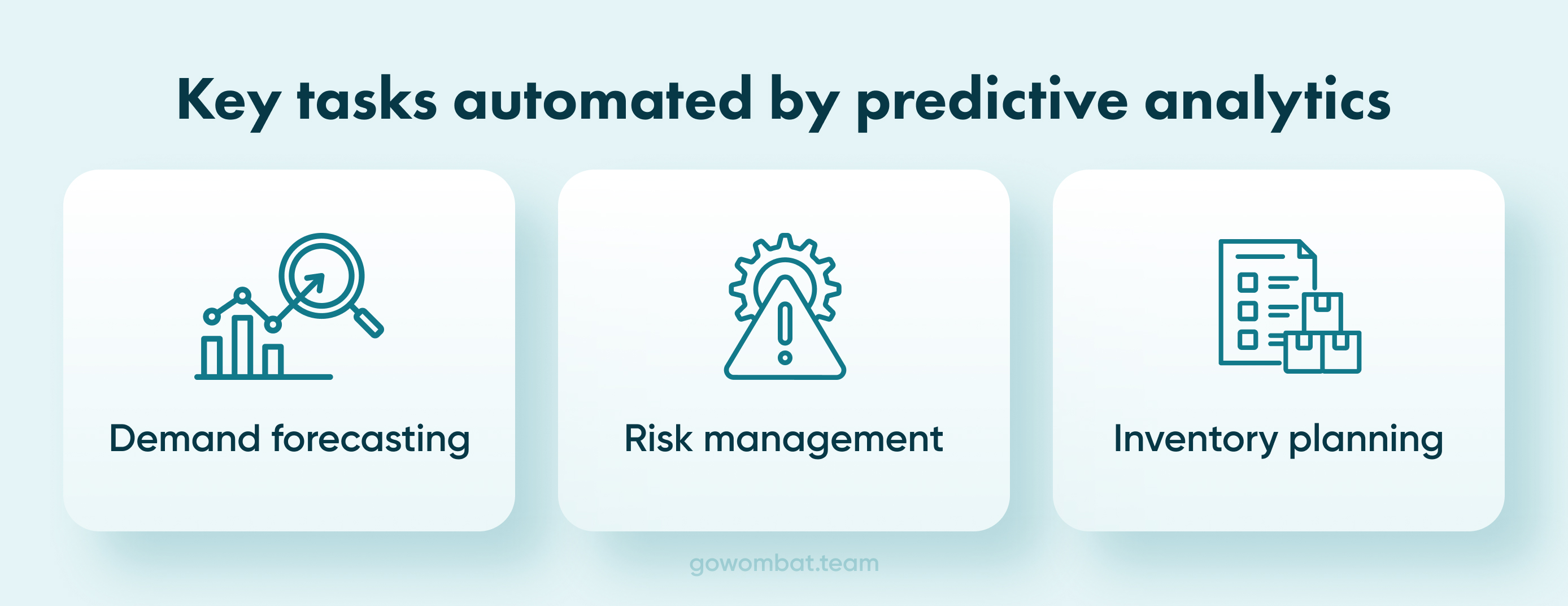

Predictive AI pulls together loads of scattered data to make smarter calls in three main areas:

1. Demand Forecasting

- It looks at historical data of sales, promos, seasonal patterns - even social media buzz - to guess how customers will behave.

- McKinsey says AI can cut forecast mistakes by 20–50%, and stop up to 65% of lost sales. That’s huge.

- Amazon uses this tech to spot upcoming rushes and move inventory closer to shoppers, fast.

2. Risk Management

- AI mixes up sensor data from IoT devices with weather reports, traffic, and shipping info to see trouble coming.

- If there’s a storm brewing near a port, AI can reroute shipments or tweak production before things go sideways.

- Real-time analytics keep companies from getting stuck in bottlenecks. Predictive maintenance jumps in when sensors spot weird activity - so stuff gets fixed before it breaks.

- Predictive AI lets teams spot issues early and make changes before they turn into real problems.

3. Inventory Management and Planning

- AI keeps an eye on stock levels and adjusts reorder points and safety stock on the fly, so companies don’t run out or get stuck with too much.

- Some global retailers are already tying warehouse sensors to AI forecasts to stay on top of inventory levels in real time.

- This cuts waste, frees up cash, and keeps shelves full. With AI running the show, supply chain teams can make smarter decisions and keep deliveries on time.

Why Use Predictive AI - and What Gets in the Way?

Predictive AI delivers big wins for logistics, but it’s not plug-and-play. You need solid supply chain solutions, good data, and teams ready to work with new tech.

Here’s what it brings to the table:

- Accuracy - it learns patterns, analyses historical data and leaves less room for human mistakes.

- Efficiency - automates the boring analysis, so teams get their time back.

- Agility - spots risks in logistics networks early and helps companies react fast.

- Profit - better forecasts mean fewer lost sales, higher customer satisfaction and lower costs.

- Savings - AI smooths out warehouse ops, streamlines shipping and cuts transportation costs, and keeps the whole supply chain resilience humming, while offering tips for long-term improvements.

But there are hang-ups:

- Integration - it’s tough to connect AI with old-school ERP systems.

- Data quality - bad or missing data messes up the results.

- Tech - lots of companies still don’t have real-time analytics.

- Culture - teams have to trust the AI - and sometimes that’s the hardest part.

How IoT Gives Supply Chains Eyes and Ears

What Kinds of IoT Devices Are Out There?

IoT is a huge network of smart, connected gadgets keeping tabs on goods, machines, and environments in real time.

Here’s what you’ll see on the ground:

- Asset trackers and GPS sensors on trucks and vans, checking routes.

- RFID tags or Bluetooth beacons on pallets and products, tracking shipments.

- Environmental sensors in warehouses and containers, measuring things like temperature, humidity, and shock.

- Sensors on conveyor belts, forklifts, and assembly lines, watching equipment health.

- Wearables - think smart helmets or wristbands - are helping keep workers safe.

These devices connect in all sorts of ways, depending on how far and how often they need to talk - 4G/5G, LoRaWAN, NB-IoT, Wi-Fi, Bluetooth.

IoT is exploding right now, with a 12% jump every year. For logistics operations, that means richer, more detailed data at every step - so companies can see what’s happening, right as it happens.

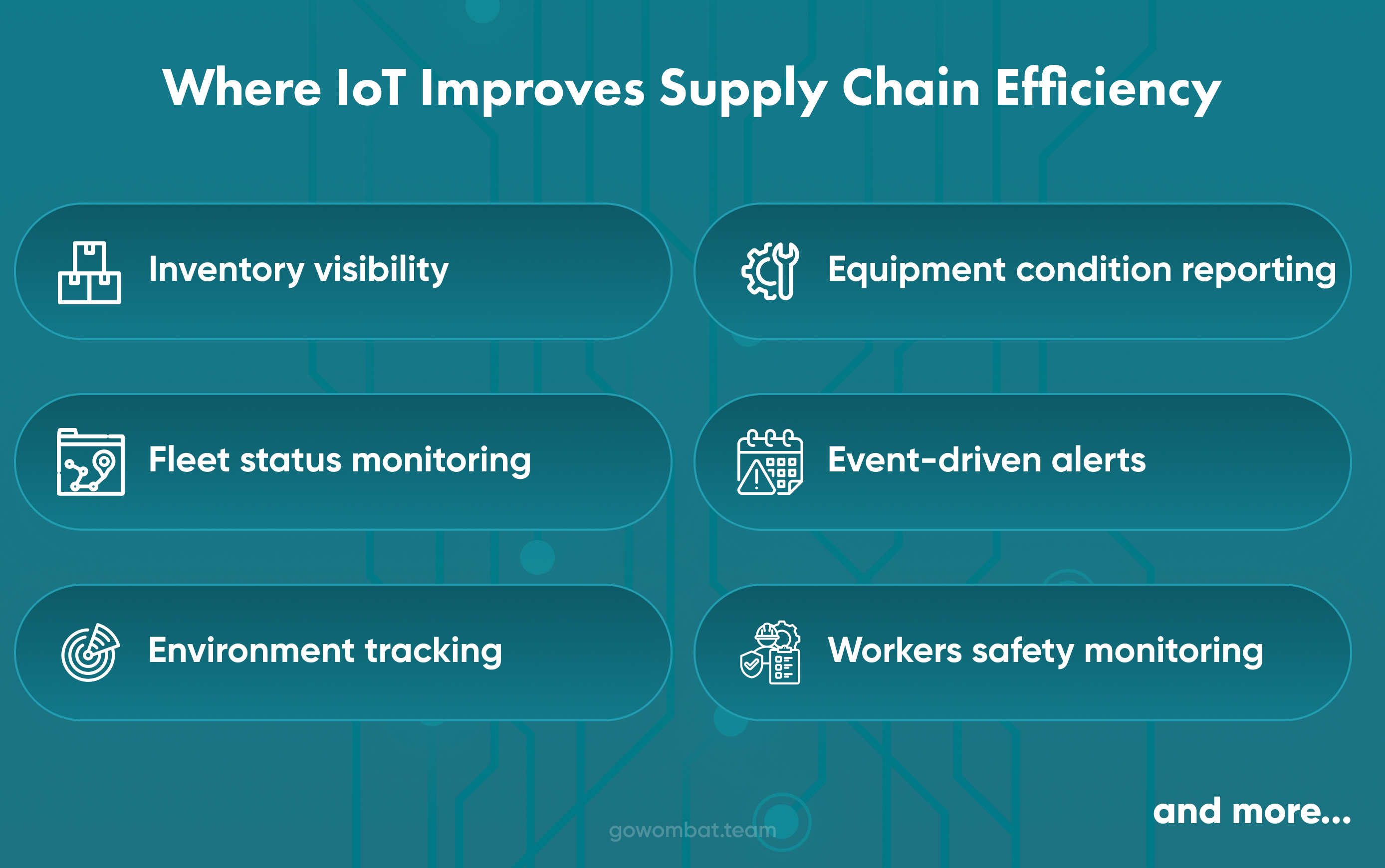

How Does IoT Boost Operational Efficiency?

IoT takes supply chains from just reacting to problems to actually predicting them. It does this by streaming live data straight into management systems to maximise efficiency.

Here’s what that actually looks like:

1. Real-time visibility

Multiple enterprises, including big names like DHL and Amazon, fit their warehouses with sensors that track inventory automatically. They always know exactly where everything is, no guesswork.

2. Instant alerts

With GPS and telematics, teams get a heads-up about delays or breakdowns. They can choose more efficient delivery routes in minutes, not hours.

3. Smarter routes, less fuel

IoT route optimisation cuts down fuel consumption, reducing waste, which saves money and shrinks your carbon footprint at the same time.

4. Smart production

On the manufacturing side, IoT sensors on machines report uptime, output quality, and energy use. This means teams can fix issues before things break and plan production with real data.

5. End-to-end transparency

With IoT devices and cloud data feeding live updates, you can see the whole supply chain as it happens - no blind spots.

What Challenges Come with IoT?

IoT brings a lot of benefits, but it’s not all smooth sailing. There are some real headaches too:

1. Security risks

Every device you connect is another target for hackers. You need strong encryption, tight access controls, and constant network monitoring.

2. Integration headaches

Trying to make technological advancements play nice with old software can create data silos if you don’t have the right APIs or standards.

3. Big upfront costs

Rolling out sensors and network infrastructure takes real investment at the start.

4. Talent shortage

A lot of companies just don’t have enough IT or data people who really get IoT.

5. Trusting the data

Not everyone’s ready to rely on automated readings of logistics planning. Some managers want proof before they trust the numbers.

Still, it’s worth it. Once you get IoT up and running, automation - from predictive maintenance to tracking shipments - makes logistics and manufacturing more resilient, efficient, and less risky.

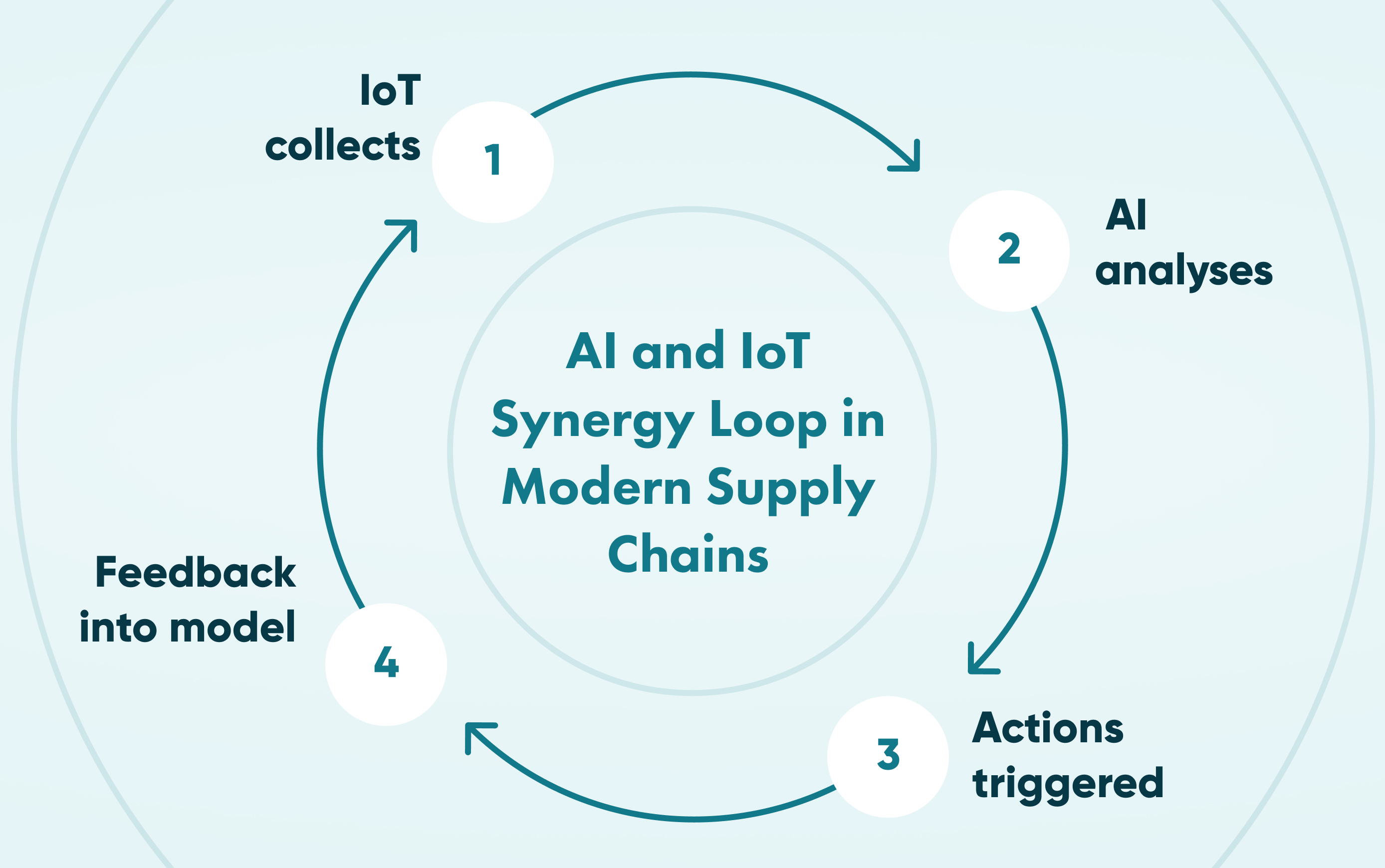

How AI and IoT Team Up to Make Supply Chains Stronger

The real magic happens when AI solutions and IoT work together. Think of IoT as the eyes, always watching and collecting data, while AI is the brain, making sense of everything and planning the next move.

When they’re connected, supply chains don’t just react - they get ahead of problems and stop them before they start. Here’s how that partnership plays out:

1. Constant data collection

IoT sensors keep tabs on equipment, vehicles, and the environment 24/7.

2. Real-time analysis

AI chews through this data to forecast demand, spot risks, and fine-tune inventory, all in real time.

3. Automatic action

AI insights kick off instant responses - rerouting trucks, rescheduling maintenance, or ramping up production before you even know you need it.

This combo gives businesses valuable insights into customer behaviour, real-time data analysis, supplier performance, and opens the door for new innovations. Some real-world examples:

- Factory machines send live production data to AI models that tweak next week’s output automatically.

- Trucks with GPS and telematics feed data to AI, which reroutes deliveries if there’s a delay or bad weather.

- Predictive maintenance uses sensor alerts to schedule repairs before anything breaks, so downtime never gets expensive.

And when the unexpected hits, predictive logistics helps companies find backup suppliers and roll out new plans almost instantly.

Key Considerations for Predictive Logistics Implementation

1. Establish strong governance practices

Clear oversight ensures predictive logistics systems operate responsibly across all three phases of planning, optimisation, and execution. This helps supply chain planners trust the technology and maintain control over cost-critical processes.

2. Prioritise data ethics and compliance

When machine learning influences staffing, delivery times, or customer-facing decisions, businesses must set safeguards that protect customers, resources, and overall supply chain operations.

3. Perform scenario and stress testing

Evaluating how models behave during market fluctuations helps avoid operational costs linked to inaccurate forecasts and prepares teams for real-world logistics disruptions.

4. Assess vendor reliability and long-term fit

Choosing technology partners that support scalable predictive logistics gives companies a competitive edge and prevents future integration bottlenecks.

5. Plan for workforce impact and skills development

Machine learning tools change how supply chain planners work. Upskilling ensures teams use new technology effectively, improving efficiency and supporting better decision-making.

6. Strengthen cultural adoption early

Predictive systems only improve customer satisfaction when people trust and understand the processes behind them. Building this mindset from day one improves cross-team alignment.

7. Evaluate digital twin readiness

Digital twins require high-quality data and strong system integration. When structured correctly, they help optimise resources, cost efficiency, and logistics performance.

8. Measure scalability and long-term ROI

Consider how predictive AI will evolve as the business grows - across all three phases - to reduce operational costs, improve delivery times, and enhance overall supply chain efficiency.

9. Ensure the solution integrates across core processes

Predictive systems should connect seamlessly with inventory, transport, and workforce planning to maximise technology value and improve customer outcomes.

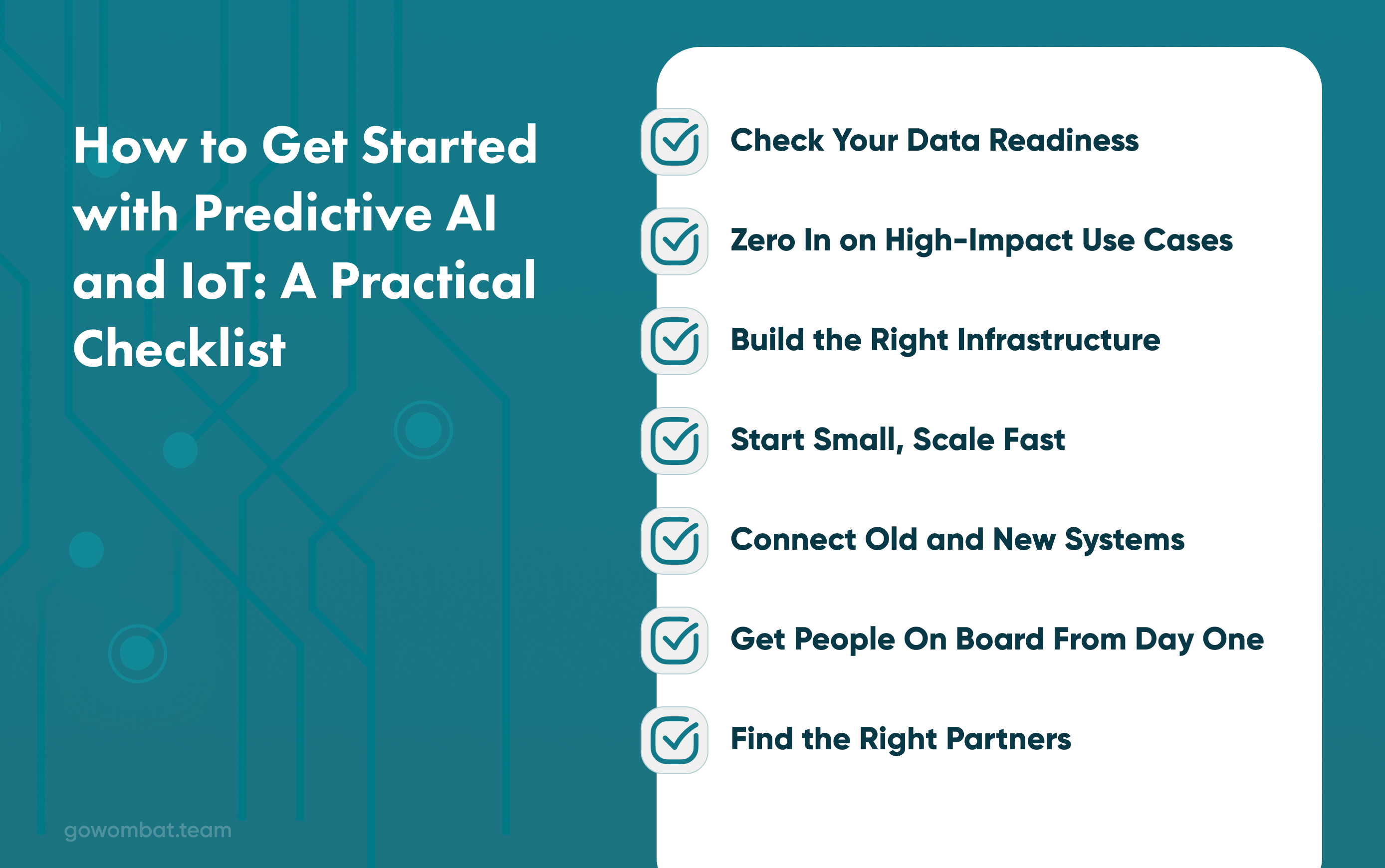

How to Get Started with Predictive AI and IoT: A Practical Checklist

Bringing predictive AI and IoT into your supply chain management can really shake things up, but it only works if you plan carefully, get your data in order, and have the right team mindset. The trick is to start small, focus on what matters, and double down on wins. Here’s how logistics and manufacturing leaders can get moving with a data-driven approach:

1. Check Your Data Readiness

Bring all your sources together under one data model, so you’re working from a single, trustworthy version of the truth and upgrade old systems.

2. Zero In on High-Impact Use Cases

Don’t try to fix everything at once. Pick a problem that really hits your bottom line, like demand forecasting, route optimisation, or predictive maintenance. Go for something you can measure and improve quickly.

3. Build the Right Infrastructure

Create a data platform - cloud or edge - that can connect all your sensors, trackers, and databases. Strong data governance and ongoing cleanup are a must.

4. Start Small, Scale Fast

Start with a pilot, prove the business value fast, then roll it out wider to reach strategic objectives.

5. Connect Old and New Systems

Don’t rip all processes out at once with large volumes of real-time and potential issues. Use middleware or APIs to let new IoT tools talk to your existing ERP or WMS.

6. Get People On Board From Day One

Supply chain optimisation needs both people who understand and trust them. Managers should use AI forecasts to help with actionable insights, not replace human decision-making - tech and people need to work hand-in-hand.

7. Find the Right Partners

Go for solutions that let you work easily with suppliers and trading partners, so your supply chain moves in real time.

Conclusion and Main Takeaways

Predictive AI and IoT are changing the game for supply chains. Instead of scrambling to react, companies get vast amounts of real-time updates and a peek into what’s coming next.

They combine sensor data and smart analytics to spot demand shifts, market conditions and possible hiccups, boosting accuracy by 20–50%. It’s a big leap from the old days of guesswork. If you want to boost efficiency, visibility, and resilience, reach out for a quote - we’ll show you how Go Wombat can help get you there.

Unlock Success with Premium Software Development

Contact us

FAQs

How does predictive AI make supply chains stronger?

Predictive AI looks at past sales, inventory, weather, market trends, and more to forecast demand, customer needs and spot risks or unforeseen events. This lets companies plan - adjust orders, get alternative suppliers, reroute shipments, and avoid running out of stock or hitting delays. The result? A sustainable supply chain you can actually count on.

What does IoT do for supply chains?

IoT devices - GPS trackers or temperature sensors - give you a live feed on where your shipments are and how they’re doing. You can get operational insights and catch problems as they happen, whether it’s a delayed truck or a temperature spike.

How do you get started with predictive AI and IoT?

Start by getting your data in order - digitise orders, inventory, supplier info. Figure out your top use-cases, like demand forecasting or tracking assets. Try out IoT sensors in one area, run a simple predictive model, and see what you learn. Build from there. And if you want things to move faster, partner with a solutions provider.

Why is real-time data such a big deal for supply chains?

When you're processing vast amounts of data instantly, you can spot problems the second they pop up - traffic jams, delays, quality issues. Live data from IoT sensors helps you make decisions on the fly. AI algorithms take it further by forecasting what’s next and suggesting smart fixes before small problems snowball. As a result, you make informed decisions and stay ahead with contingency plans.

What challenges come with adopting these technologies?

You’ll run into a few bumps: making sure your data is clean, connecting new tech with old systems, keeping costs in check, and locking down security on connected devices. Plus, your team needs to trust AI insights. The fix? Plan carefully, test things out first, and bring in data experts when you need them.

How can we help you ?